OPTISCRAPS: Lifting the locks of the green steel industry through the optimized use of scraps and their residuals and the dynamic design of alloys

Coordinator: Sébastien ALLAIN

IJL – Institut Jean Lamour

(UMR 7198 Univ. Lorraine/CNRS)

Keywords: steel, recycling, scraps, hydrid modelling, combinatorial metallurgy, machine learning, segregation, high throughput, optimization, phase transformation, mechanical properties microstructure, advanced analytical characterization

The OPTISCRAPS project takes place in the context of the decarbonization of the steel industry and the upcoming cessation of blast furnaces. These changes will lead to a massive expansion of electricity-based processes (Electric Arc Furnace) and an increase in the consumption of recycled scrap materials. These scraps introduce residual elements that cannot be removed from liquid steel using current manufacturing and refining technologies. These elements impact the formation of microstructures and the final properties of the produced steel (toughness, ductility, weldability, etc.).

The limited availability of high-quality scraps, i.e., those with low levels of residual elements, will inevitably lead to speculative market pressures and usage competition. In order to enable the national and European steel industry to maintain a competitive edge, the OPTISCRAPS project aims to develop and implement metallurgical models that allow for dynamic control of downstream manufacturing processes (continuous annealing of flat products), incorporating the variability of these new residual elements (Mo, Sn, Sb, As, etc.). However, there is a lack of knowledge regarding the potential effects of these chemical elements (thermodynamics, segregations, phase transformations, mechanical properties). This “Science of Dirty Alloys” is a well-identified challenge to enable the emergence of sustainable and circular metallurgy. Given the numerous possible combinations of these residual elements, whether intentional or incidental, only the implementation of high-throughput methods, supported by automated learning models, will allow for the study of the respective effects of these elements and their interactions within the industry’s expected timelines.

To achieve these objectives, the scientific strategy consists of three highly interconnected and interdisciplinary domains:

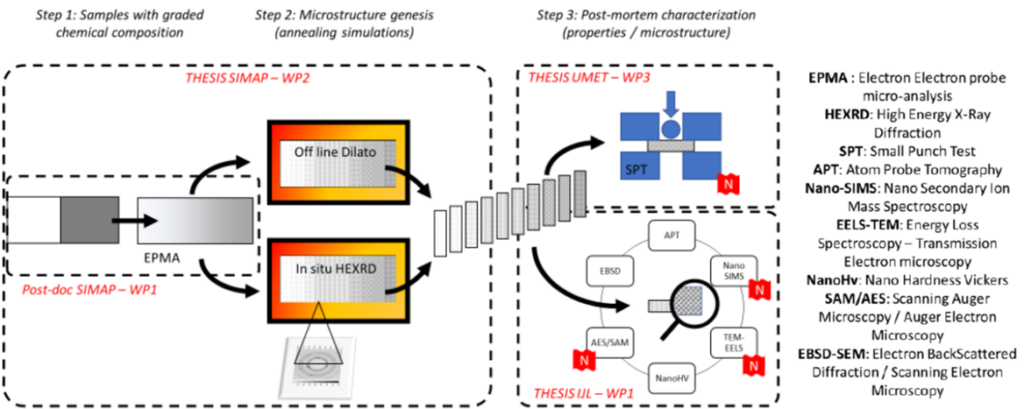

• Design and in situ characterization of microstructures using high-throughput approaches.

• Advanced multiscale characterization of post-mortem microstructures.

• Hybrid multiscale modelling assisted by automated learning methods.

The main innovations of the project will involve:

• Deploying combinatorial metallurgy tools on multi-constituent systems with numerous chemical elements, albeit in very dilute concentrations, complementing approaches already in development for major elements in the DIADEM program.

• Developing a methodology and skills to quantify these residual elements and their segregations in the steel microstructure throughout the entire process (benchmarking various advanced techniques: APT, EELS-TEM, AES/SAM, nano-SIMS).

• Extending high-throughput characterization methods in combinatorial metallurgy to mechanical properties (SPT).

• Developing hybrid metallurgical metamodels that couple processes, microstructures, and properties. These models are based on physics but enhanced by automated learning methods that combine numerical and predictive performance.

• Identifying new products that are tolerant to impurities, allowing the French steel industry to become more resilient in the face of the expected volatility in scrap metal prices.

The consortium involves five French academic laboratories (IJL, GPM, SIMAP, UMET and PIMM) and the private research center ArcelorMittal Maizières Research, supported by LIST research center. They all have complementary expertise in material development and characterization, primarily support human resources (PhD and post-doc studies) and associated laboratory operations. The project will also leverage the platforms developed under the DIAMS (combinatorial alloy development and in situ characterization on a synchrotron beamline) and DIAMOND (data management from experiments) projects.