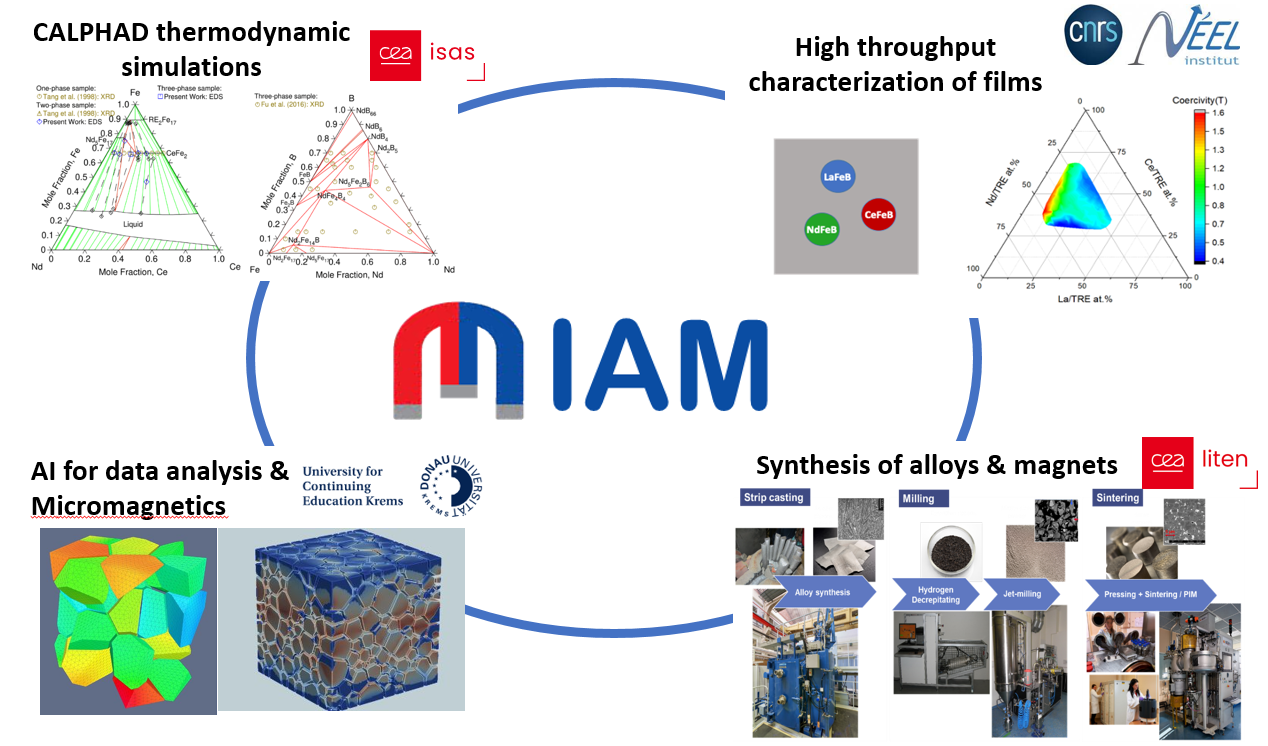

MIAM: Accelerating the discovery of innovative permanent magnets with reduced content of critical rare earths

Coordinator: Julie MAISONNEUVE

CEA LITEN/DTNM

Keywords: New Rare Earth Lean Permanent magnets, Thermodynamic simulations, High-throughput thin film synthesis and characterization, Bulk magnet fabrication, Artificial intelligence, Micro-magnetic simulations, substitution of critical elements, Low carbon energies, Pilot magnet fabrication line, Magnets by design

Rare-earth magnets are necessary for the operation of electrical machines, improving their efficiency and compactness. They are particularly effective for traction motors and generators installed in offshore wind turbines. Magnets therefore play a key role in the transition to low-carbon transport and energy. Against a backdrop of strong growth in demand for these components, the minimisation of rare earth content in magnets meets the dual challenge of securing supplies and reducing environmental impact.

This breakthrough could be achieved by replacing current R2Fe14B type magnets with a new family of RT12-xMx type magnets, which crystallise in the ThMn12 structure and possessing equivalent magnetisation (R = rare earth, T = transition metal, M = stabilising element). The rare earth content would then be reduced by 30 to 50%. Numerous combinations of R (Nd, Sm, Ce), T (Fe, Co) and M (Mo, Ti, V, etc.) elements are possible in this family of materials. The diversity of compositions and processing parameters to be investigated on a short time scale is not compatible with a conventional approach, but requires the implementation of high-throughput fabrication and characterisation methods and prediction of the final properties of the magnets using artificial intelligence.

The MIAM project therefore aims to propose a relevant methodology for the design of these magnetic materials by covering all the microstructure scales involved in obtaining the magnet’s final performance. It covers a theme that is not yet addressed in the PEPR DIADEM programme, while at the same time it is connected to several of the programme’s targeted platforms and projects.

The consortium brings together partners who are leaders in their fields: CEA-LITEN, which has a pilot line for the study of magnet production processes that is unique in France, CEA-DES, which specialises in the development of thermodynamic databases (CALPHAD), and the Néel Institute of the CNRS, which is using the thin-film combinatorial approach to study hard magnetic materials and is developing original high-throughout magnetic and structural characterization tools (in the latter case through its management of one of the French CRG lines at the ESRF). The UKW group in Austria, a pioneer in the digital design of magnets using machine learning methods and micromagnetic simulation, is also involved in the project.

In addition to downstream projects dedicated to the creation of a pilot magnet manufacturing line, the MIAM project will provide an opportunity to carry out the scientific and technological resourcing work needed to prepare for the transfer.