GreenFOAM: Accelerated discovery and optimization of high-performance green foams with controlled hierarchical architecture by light-driven processes

Coordinator: Arnaud SPANGENBERG

IS2M – Institut de Science des Matériaux de Mulhouse

(UMR 7361 CNRS/Univ. Haute-Alsace)

Keywords: Non Isocyanate Polyurethane (NIPU), Ring Opening Metathesis Polymerization (ROMP), Self-foaming and degradable polymer, Mechanic of polymer foam, Flow chemistry, Light induced processes, Volumetric Additive Manufacturing (VAM), Frontal PhotoPolymerization (FP), Hightroughput X-Ray Tomography, Artificial Intelligence.

Every year, over 600,000 tonnes of foam are produced for bedding, furniture, seating, sporting goods and many other everyday objects.

Initially adopted in the transport industry to lighten structures and minimize energy consumption, polymer foams now play a major role in packaging, electronics, furniture and construction by virtue of their exceptional lightness, shock-absorbing properties in addition to low thermal and electrical conductivity. In view of the industrial and economic potential of this sector, as well as the involved environmental challenges, the design of higher-performance, degradable polymer foams, and the development of new, more efficient and environmentally-friendly methods of these manufacture, represent a considerable challenge.

However, foams are materials with a complex architecture. They are structured according to three-dimensional arrangements that are more or less complex, periodic and, more often than not, random. The design scope of these materials encompasses a considerable number of combinations, making it difficult to search for an optimal design, whether via experimental measurements or numerical simulations. In particular, the complex and frequently stochastic structure of foams makes it difficult to develop constitutive models for these architectural materials.

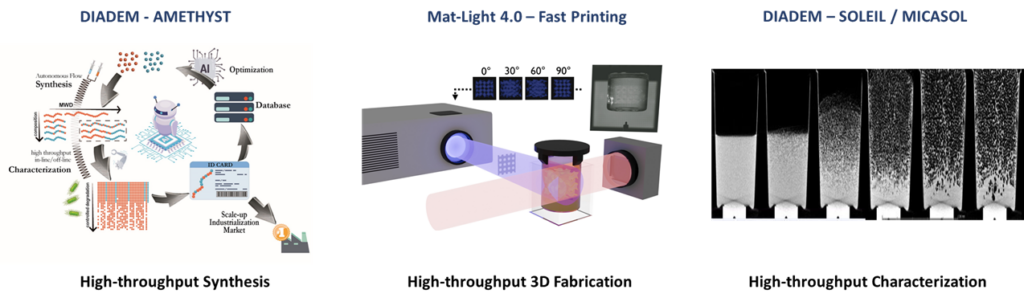

The aim of the GreenFoam project is to implement a scientific approach combining rationalized, high-throughput experimentation, numerical simulation and artificial intelligence to accelerate the discovery of more eco-responsible, higher-performance foams.

Our strategy is based on 4 pillars:

- the synthesis of new isocyanate-free, degradable and photosensitive pre-polymers,

- the fabrication of macroscopic 3D architectures using photo-induced processes,

- the characterization of foaming phenomena and mechanical properties under controlled environments,

- the use of artificial intelligence to determine optimal hierarchical architectures to achieve the targeted properties.