ATHERM_COAT: Accelerated thermodynamics and high-throughput data for optimizing component coatings for the energy transition

Coordinator: Ioana NUTA

SIMaP – Sciences et Ingénierie, Matériaux, Procédés

(UMR 5266 CNRS/Grenoble INP/Univ. Grenoble Alpes)

Keywords: Mass spectrometry, Thermodynamic Data Determination, Chemical precursors, DLI-MOCVD and ALD process optimization, Simulation, Constrained digital design

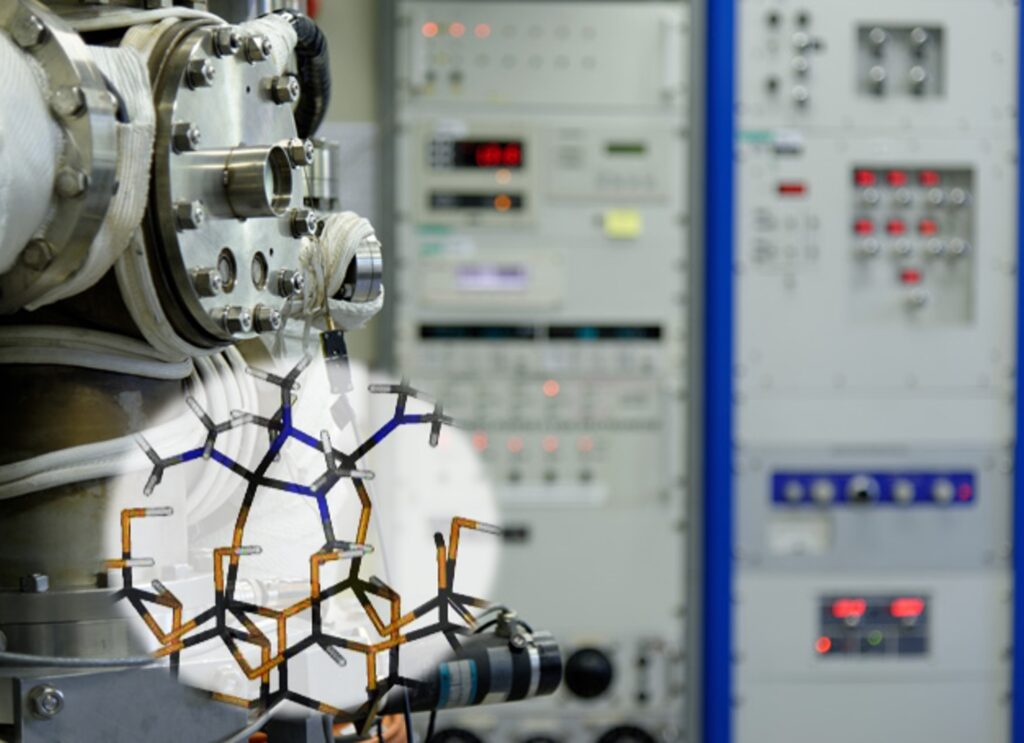

The priority objective of the ATHERM_COAT project is to set up a thermodynamic data acquisition tool on organometallic precursors and their decomposition products in order to be able to accelerate the development of CVD and ALD coating solutions and to increase our scientific sovereignty. and technological in this area, in particular for applications concerning energy and digital transitions. This tool will strengthen a state-of-the-art national mass spectrometry platform that is strategic for the generation of thermodynamic data for materials science and engineering.

One of the important objectives of experimental thermochemistry is to produce sufficient thermodynamic data to allow the calculation of heat and the free energy of any chemical reaction for the development of materials, coatings as well as for carrying out calculations or simulations. behavior in service (for example for corrosion behavior).

In the case of the manufacture of coatings by chemical vapor deposition CVD (Chemical Vapor Deposition) and ALD (Atomic Layer Deposition), one of the first steps to control the deposits is the choice of precursors (molecules which are transported in the gaseous state on the surface of the substrate to be covered lead to the formation of the deposit). Vapor pressure and stability at vaporization, transport and deposition temperatures are determining properties for choosing the molecular precursor appropriate to the conditions of obtaining and desired properties of the thin layer. Knowledge of the gas phase during thermal cracking of the precursor is also necessary in order to analyze the possible mechanisms that lead to the formation of the deposit. The identification of the molecules playing a role in the deposition and the constitution of a base of their thermodynamic data are also prerequisites for a simulation of the deposition process.

The application case and methodological demonstration chosen in the ATHERM_COAT project is that of the development of coatings resistant to oxidation at high temperatures, using technologies such as DLI-MOCVD (Direct Liquid Injection Metal Organic Chemical Vapor Deposition) and ALD (Atomic Layer Deposition). The targeted applications of these coatings include materials for high-temperature water electrolyzers for hydrogen production and materials for nuclear fuel cladding.

Furthermore, once the coatings have been developed, they can also be optimized with regard to their performance in service as well as from an eco-design perspective by minimizing the critical and/or toxic elements that compose them. Thermodynamics (determination of stable and metastable phase diagrams on new systems) coupled with artificial intelligence can to a certain extent make it possible to guide this type of choice and accelerate this optimization of solutions.

The generic methodological approach developed as part of the targeted ATHERM_COAT project will then be generalizable to the resolution of numerous scenarios requiring the development of innovative coatings for the energy and digital transitions.