Two-photon light polymerization

Description

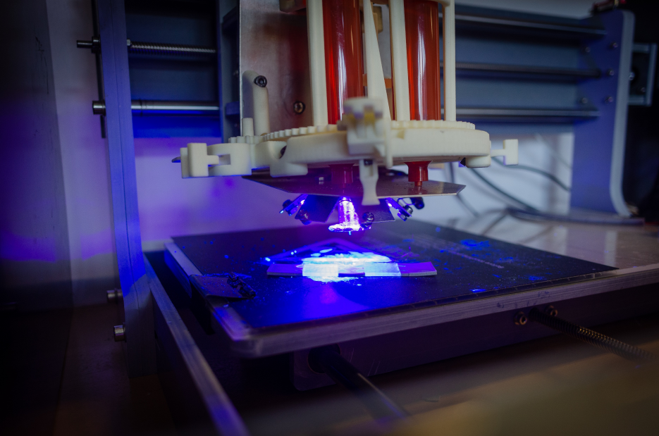

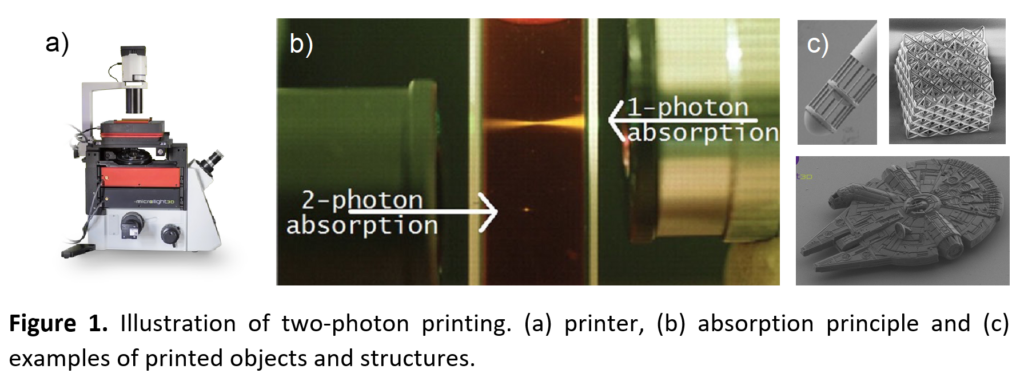

Funded as part of the targeted ARTEMIS project and co-financed by the PIA EUR-EIPHI BOOST-4D project, this equipment aims to print 3D/4D objects and structures – in polymers, elastomers, hydrogels and their composites – using micrometric scale from one or more photo-activatable materials by exploiting two-photon absorption. This equipment, which uses the two-photon photopolymerization or two-photon printing technique, strengthens the UTBM/ICB TITAN platform on the Sevenans site. Printable materials are transparent at the wavelength used by the pulsed laser, meaning nothing happens within the focusing cone. It is therefore only at the focal point, in a small elementary volume called a “voxel”, that the material can simultaneously absorb two photons in the visible and near infrared range. A chemical reaction begins with a photoinitiator present in the monomer, which converts light energy into chemical energy, thus starting the polymerization of the liquid monomer inside the voxel (Figure 1).

Location

UTBM, ICB UMR 6303 CNRS, TITAN Platform, Sevenans Site (90400).

Contacts

Platform manager / Coordinator of the associated targeted project: Frédéric DEMOLY

Technical characteristics

Fabrication of structures at height resolution (< 0.2 µm) ranging from several tens of micrometers in height to the centimeter scale. Possibility of printing several materials on the same structure, with the capacity to integrate fluidic, photonic, optical or magnetic functions. Possibility of printing on existing substrates. Versatile manufacturing system in terms of materials (polymers, elastomers, hydrogels, which can integrate nanoparticles).

Associated targeted project