Nanoparticles liquid route

Description

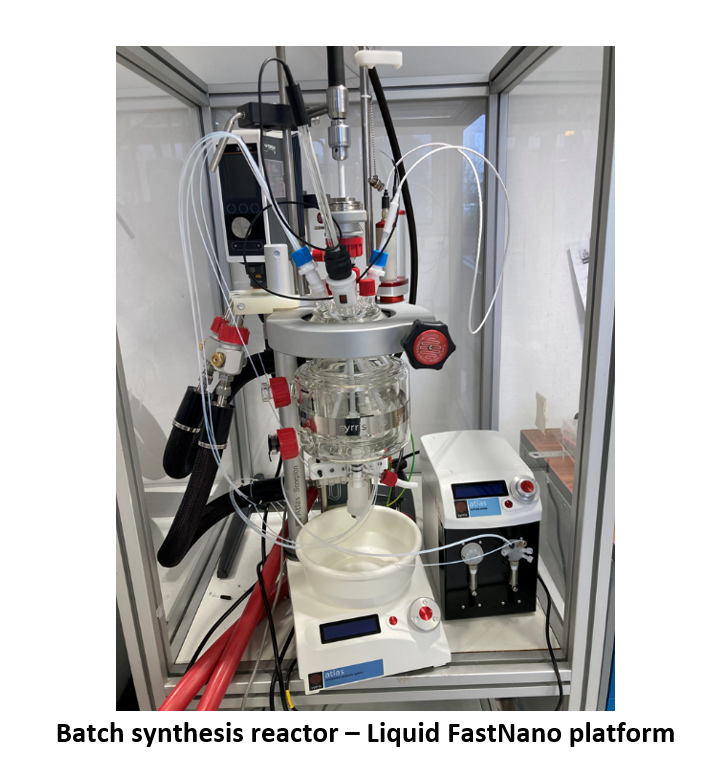

This nanoparticle synthesis platform in solution consists of three batch or continuous flow synthesis devices, which can be coupled with SAXS, UV-Vis and Raman analyses. The first device is a synthesis reactor for volumes from 50 ml to 1 L, with automated control of temperature, pH, reagent injection and agitation. The second device is a thermostatically controlled reactor under continuous flow with control of the injection and mixing of the reagents via flow control. This device will in the future be coupled to a feedback loop to adjust the flow rates in real time during synthesis. The final device is a liquid handling robot to prepare hundreds of samples for subsequent high-throughput screening. Controlling the temperature and mixtures will make it possible to explore different synthesis and aging conditions of materials.

Localisation

CEA Paris-Saclay, NIMBE, LIONS, SWAXS Laboratory.

Contacts

Responsible for the platform: Mark LEVENSTEIN

Associated targeted project coordinator: Yann LECONTE

Technical characteristics

Batch reactor: Atlas Reactor (Syrris)

Temperature up to 250°C

pH control from 1 to 14 with an accuracy of ±0.2 pH

Volumes from 50 mL to 1 L possible

Heidolph Hei-Torque Stirrer

Injection of up to 2 different reagents if pH control is not used

Continuous flow reactor: Micro- and milli-fluidic devices

Syringe pump or pressure based injection of 2 to 4 liquids

Heating up to 100°C with the possibility of future hydrothermal upgrades

Flow rates from 50 µL/min to 10 mL/mi

Liquid handling robot: Flex (Opentrons)

Temperature control between 4°C and 95°C

Orbital shaking from 200 to 3000 rpm (room temperature to 95 °C)

Handles 12 96-well plates; Container sizes up to mL are possible

Targeted associated project