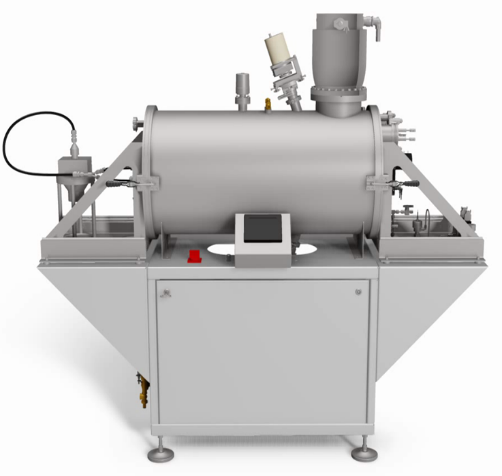

Nano-hybrid 1D/2D (ANAPURNA)

Description

The ANAPURNA platform (Artificial-iNtelligence-Assisted Platform for Ultimate pRoduction of NAnocomposite coatings) is based on a “safe-by-design” process for developing nanostructured coatings composed of nanoparticles coated in a matrix on 2-inch substrates by combining the nanoparticle jets with magnetron sputtering. The process makes it possible to independently choose the chemical nature of the nanoparticles and that of the matrix in a wide range.

Location

Commissariat à l’énergie atomique et aux énergies alternatives (CEA-Saclay).

Contacts

Platform manager: Olivier SUBLEMONTIER

Associated targeted project coordinator: Yann LECONTE

Technical characteristics

The nanoparticles are delivered aerodynamically using aerodynamic lenses. The reactor can be coupled to the FastNano Flame Pyrolysis Spray reactor or use an aerosol generator powered by a suspension of previously synthesized nanoparticles. The prototype includes 3 aerodynamic lenses allowing the simultaneous or sequential deposition of 3 different types of nanoparticles on the same surface of a substrate. The material making up the matrix is deposited simultaneously by magnetron sputtering using 3 cathodes which can be used either simultaneously or sequentially. The resulting deposit can therefore be a complex and controlled assembly in its thickness, homogeneous on its surface, giving rise to multifunctional coatings. The fully automated ANAPURNA platform will be equipped with a system for in situ and real-time characterization of the elemental composition of coatings by laser-induced plasma spectroscopy (LIBS). AI processing of LIBS data in situ and in real time within a few years will allow a posteriori 3D elementary analysis of the coating, and therefore faster convergence towards the desired nanocomposite.

Associated targeted project