Hybrid PVD reactor

Description

The hybrid PVD (Physical Vapor Deposition) equipment is intended for treatments by vacuum processes and more particularly the development of metallic or ceramic coatings by magnetron cathode sputtering and by the PECVD (Plasma Enhanced Chemical Vapor Deposition) process. It allows the production of coatings at temperatures close to ambient temperature.

Location

UTT/LASMIS/Antenne de Nogent

Technical characteristics

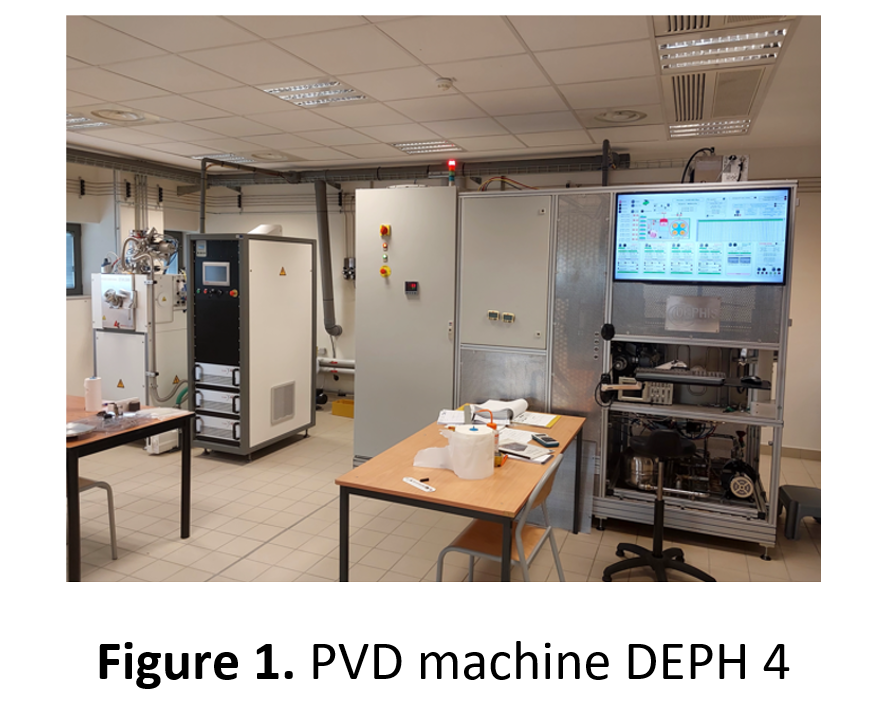

This is a low-pressure deposition machine that can deposit from 4 targets (diameter 200 mm) simultaneously (Figure 1). The main features are:

- Ultimate vacuum: secondary, pressure < 3.10-6 mbar

- Four cathodes for sources with a diameter of 200 mm

- Four 3kW pulsed DC/DC power supplies

- A HIPIMS power supply

- An RF power supply for polarization of the substrate holder

- A turntable (variable speed up to 20 rpm).

- Six fully equipped gas lines (Ar, O2, CH4, N2, C6H12 and Si(CH3)4)

Associated targeted project

A-DREAM

Accelerated development of corrosion-resistant materials