High-throughput platform for the implementation and characterization of polymer matrix composites

Description

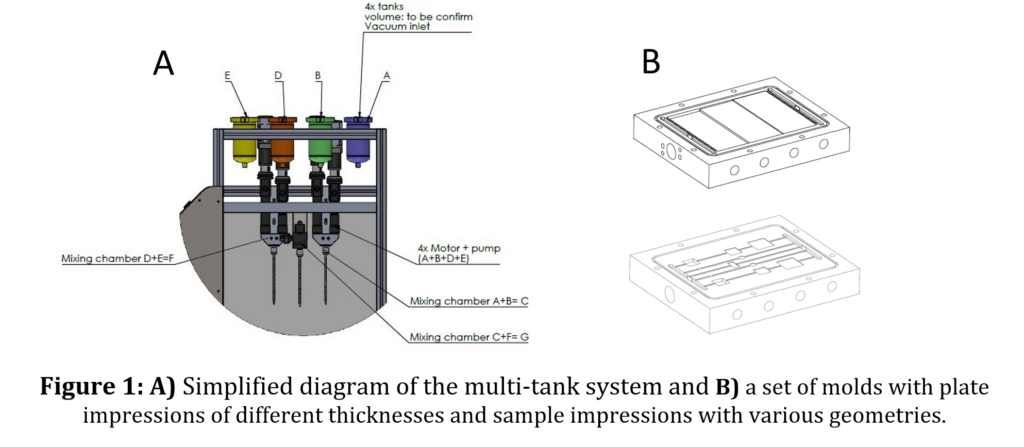

The opening of the platform is planned for the last quarter of 2024. This will include an automated system for the preparation and implementation of thermosetting networks (composites and nanocomposites). Thanks to its multi-tank technology (see Figure 1) and a set of connected and self-heating molds, the equipment is capable of simultaneously programming a series of formulations from the master batches containing the fillers. It also ensures control of the entire process, from injection into the mold to the high temperature baking phase. The dedicated human-machine interface (HMI) guarantees optimal traceability of all the parameters of the implementation process and their physico-chemical and physical characterizations.

Location

IMP Laboratory, UMR-CNRS 5223 INSA de Lyon

Contacts

Responsible for the platform: Sébastien PRUVOST

Coordinator of the associated targeted project: Jean-François GERARD

Technical characteristics

System for preparing and injecting master batches of thermosetting networks:

- Viscosity range between 10 – 50,000 cP; Temperature Range: 20 – 100°C

- Real-time control of viscosity variation as a function of temperature

- Stirring speed up to 800 rpm; Vacuum < 50 mbar for optimal degassing

- Set of connected, self-heating (up to 200°C) and modifiable molds

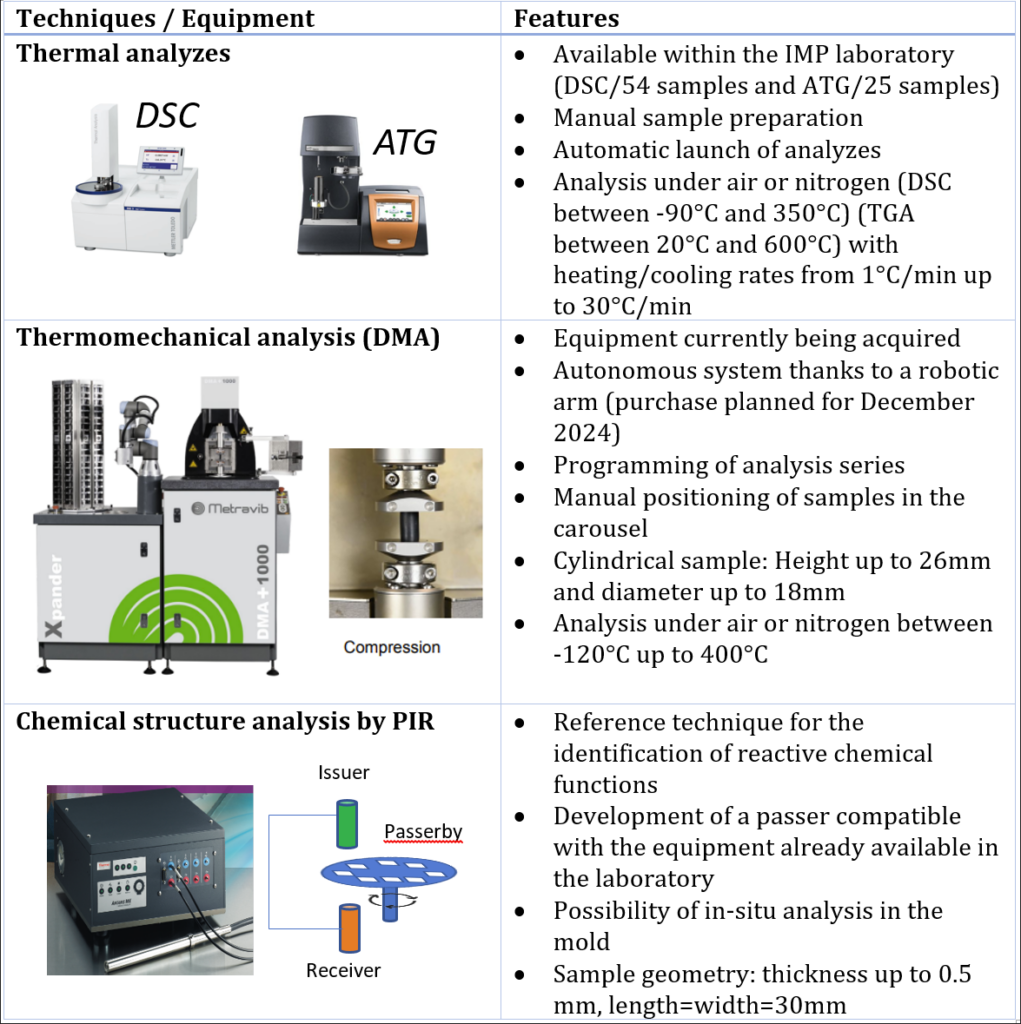

High-throughput characterization platform:

Associated targeted project