DLI-MOCVD ANTIDOTE equipment

Description

The DLI-MOCVD ANTIDOTE (Direct Liquid Injection-MetalOrganic Chemical Vapor Deposition) equipment is CVD equipment that operates by injection of liquid solution. The solutions are composed of a solvent and a precursor. The precursors are organometallics which are deposited at low temperatures. This equipment makes it possible to produce coatings on complex surfaces at temperatures of a few hundred °C.

Localisation

CEA-Saclay, DES/ISAS/DRMP/S2CM, Building 458.

Caractéristiques techniques

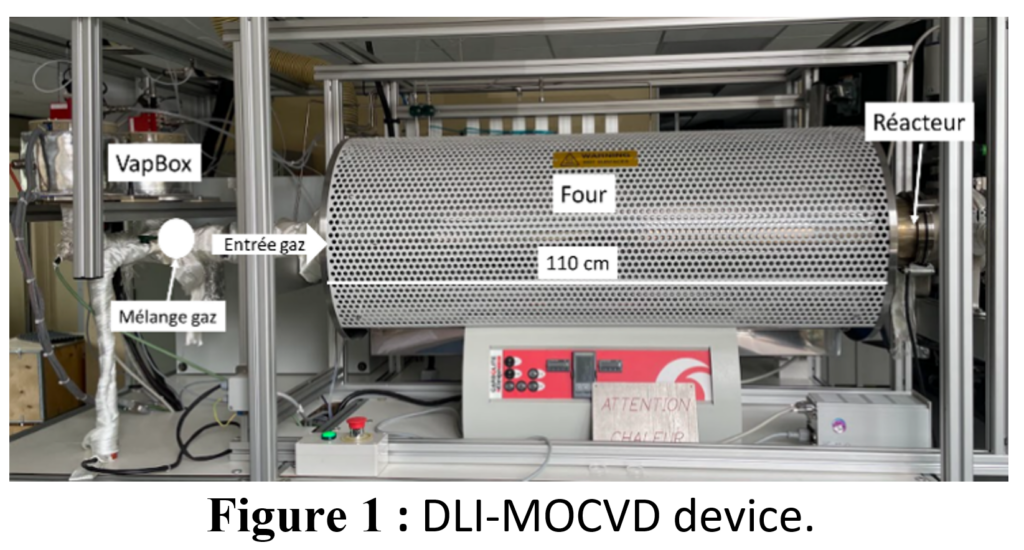

The DLI-MOCVD ANTIDOTE equipment is made up of a tubular furnace into which a steel reactor measuring 15 cm in diameter and 130 cm long is slipped. It is possible to replace the reactor with a smaller reactor or even to replace it with a tube to cover the interior. Its isothermal zone is 90 cm long. The precursor is injected in liquid form via a solution composed of the precursor and a solvent. The solution is injected into a vaporization unit called a VapBox. The reactive or dilution gases are injected downstream of the vaporization of the solution and upstream of the reactor. Figure 1 shows a photo of the installation.

The coating is carried out under vacuum between 2 and 100 mbar. The deposition temperature is between 150°C – 500°C depending on the precursors and the desired coating speed.

Currently, it is possible to produce coatings of metal oxides and chromium carbide. The deposition of mixed oxides is also possible.

Associated targeted project