DARMiColS: Accelerated Development of Coatings and Microstructures by Cold Spray

Description

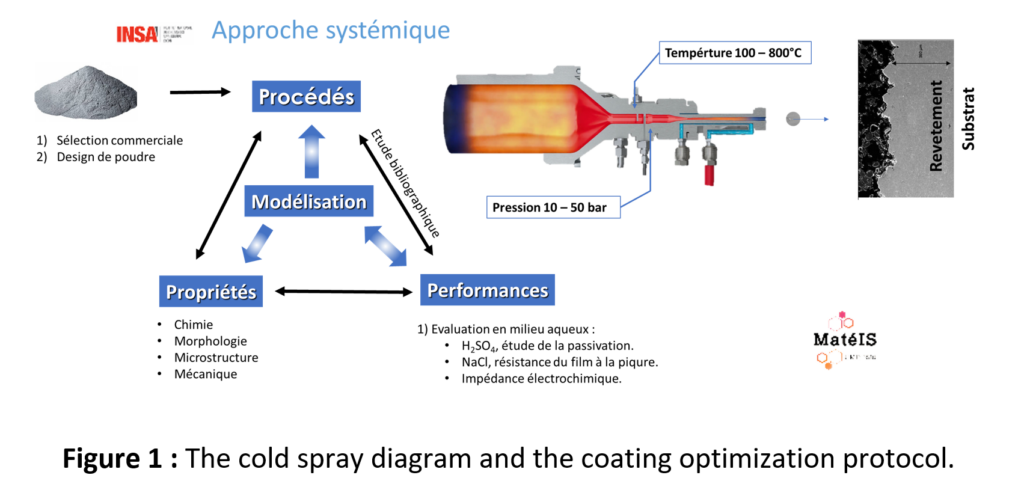

The DARMiColS device allows the development of coatings by cold powder spraying. The projection speed gives the particles impact and adiabatic shear conditions which contribute to the cohesion and densification of the coatings, thus limiting the connective porosity and inter-particle oxidation which are observed in the case of thermal projection. classic. This device makes it possible to consider the projection of all types of materials. The morphological, microstructural and chemical qualities of these coatings make it possible to consider anti-corrosion or tribological applications.

Location

INSA Lyon, Laboratoire MATEIS, Bât Blaise Pascal

Contacts

Responsible for the platform: Bernard NORMAND

Coordinator of the associated targeted project: Fanny BALBAUD

Technical characteristics

Cold spray is distinguished by its projection process at low temperatures, lower than the melting temperature of the material used. The particles are accelerated to speeds between 300 m/s and 1200 m/s. The speed mainly depends on the morphology and size of the powder, the temperature and the pressure in the projection nozzle. The DARMiCoLS device allows an operational temperature of up to 800°C and a pressure of 50 bars. The metal coatings produced to date are based on Zn, Al, Cr, stainless steel, Ni base and core-shell particles.

Figure 1 summarizes the scientific approach implemented for the optimization of coatings produced by cold spray.

Associated targeted project