Combinatorial growth of heterostructures by PLD/PVD

Description

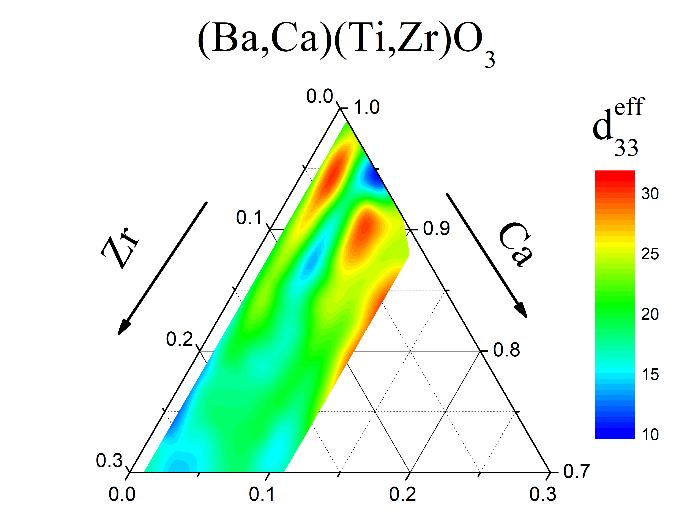

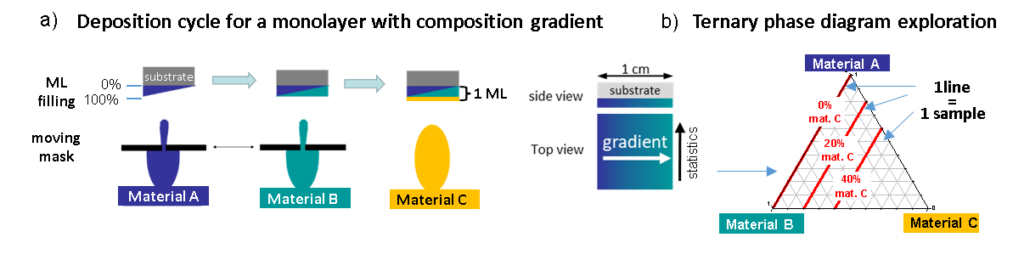

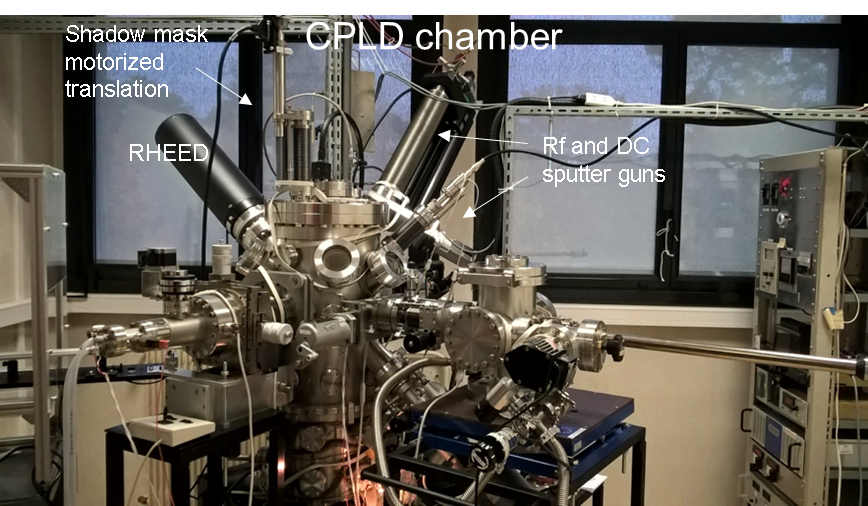

GREMAN has refined Combinatorial heterostructure growth by Pulsed Laser Deposition (CPLD) technique for the last 15 years. CPLD is based on the ability to deposit, on a single substrate and in a single deposition run, a layer with continuous in-plane chemical modulations and / or thickness variation. The stacking of modulated layers allows synthesizing a collection of continuously varying heterostructures within the same sample. This method guarantees identical growth conditions and eliminates sample variability from run to run. It requires a local control of composition and thickness anywhere on the substrate, obtained by synchronizing target selection, laser pulses and shadow mask movement. One deposition cycle corresponds to the growth of single monolayer (ML) with a continuous in-plane composition gradient (figure a). Repetition of this cycle leads to the desired total thickness. A platform of local and high throughput characterizations has been set-up to correlate stoichiometry variations (WDS, ESCA) with structural and electric properties (see platform “Structural and electrical characterization of 2D gradient layers”) in a statistical manner. An original approach involving three targets is used to study ternary phase diagrams (figure b) keeping statistical characterization.

Based on PLD, the CPLD is best suited for epitaxial or polycrystalline oxide heterostructures. Coupled with two in-situ magnetron sputter guns (dc/rf), it allows the deposition of modulated metal/oxide heterostructures potentially interesting for e.g. spintronics.

Location

Laboratoire GREMAN, UMR-7347 CNRS-Université de Tours.

Contact

Platform manager / Coordinator of the associated targeted project: Jérôme WOLFMAN

Technical characteristics

- Sample size 10 mm x 10 mm, total heterostructure thickness 1-300 nm

- Deposition temperature 750°C max under 0.3 Torr of O2.

- Laser ns KrF: 248nm, max fluence 2.5 J/cm2, 10Hz, homogenized beam

- Up to 8 targets (PLD) + 2 sputter guns (dc/rf)

- In situ high pressure (up to 0.3 Torr) RHEED (grazing incidence electron diffraction)

- ESCA/UPS analysis chamber coupled to PLD chamber (to be installed Q1 2025)

Targeted associated project