Atm-PECVD equipment

Description

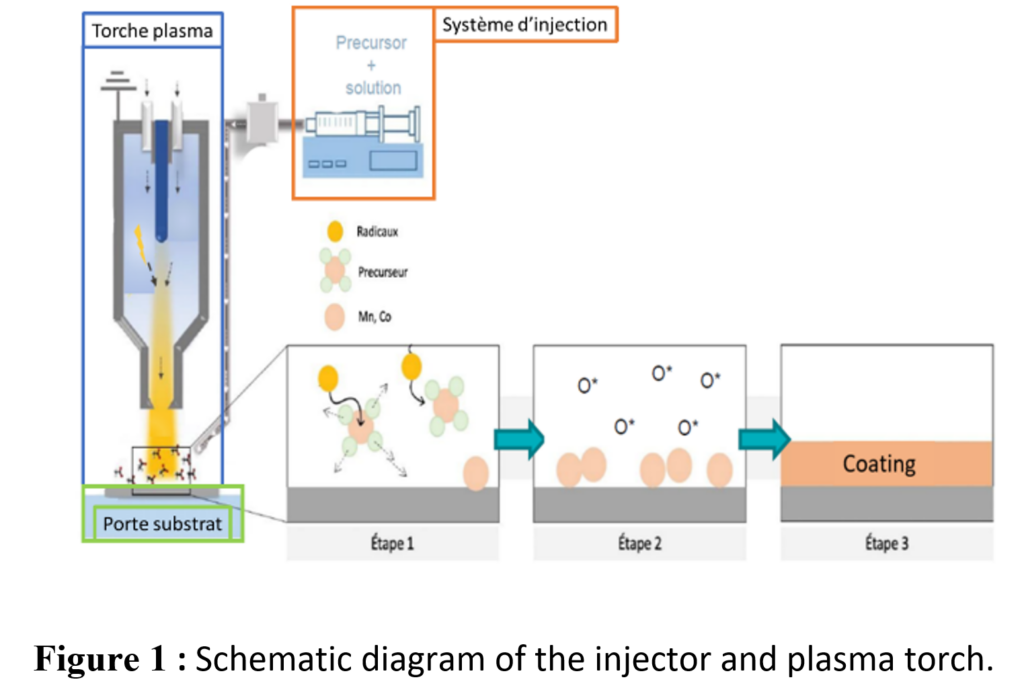

The Atm-PECVD (Atmospheric-Plasma Enhanced Chemical Vapor Deposition) equipment allows surface functionalization and/or CVD coatings assisted by plasma at atmospheric pressure. This equipment makes it possible to produce coatings on complex surfaces at temperatures close to ambient temperature up to a few hundred °C.

Location

CEA-Saclay, DES/ISAS/DRMP/S2CM, Building 458.

Technical characteristics

The deposition device is composed of a plasma torch coupled with a liquid injection system. The liquid includes a solvent and a solution-forming precursor. This solution is injected and nebulized above the substrate in plasma emission. Plasma allows better reactivity of the precursor with the substrate. This opens up the possibility of producing coatings at lower temperatures than during conventional CVD. The temperature of the substrate can vary from room temperature to a few hundred °C during deposition. The temperature is defined according to the precursor, the substrate and the desired deposition speed. Figure 1 shows a schematic diagram of the torch and the injection device. The deposition system is connected to a robot which makes it possible to coat a 50 cm substrate of complex shape.

It is possible to develop, with this equipment, nitride and oxide coatings. A deposit of mixed oxides or nitrides is also possible.

Associated targeted project