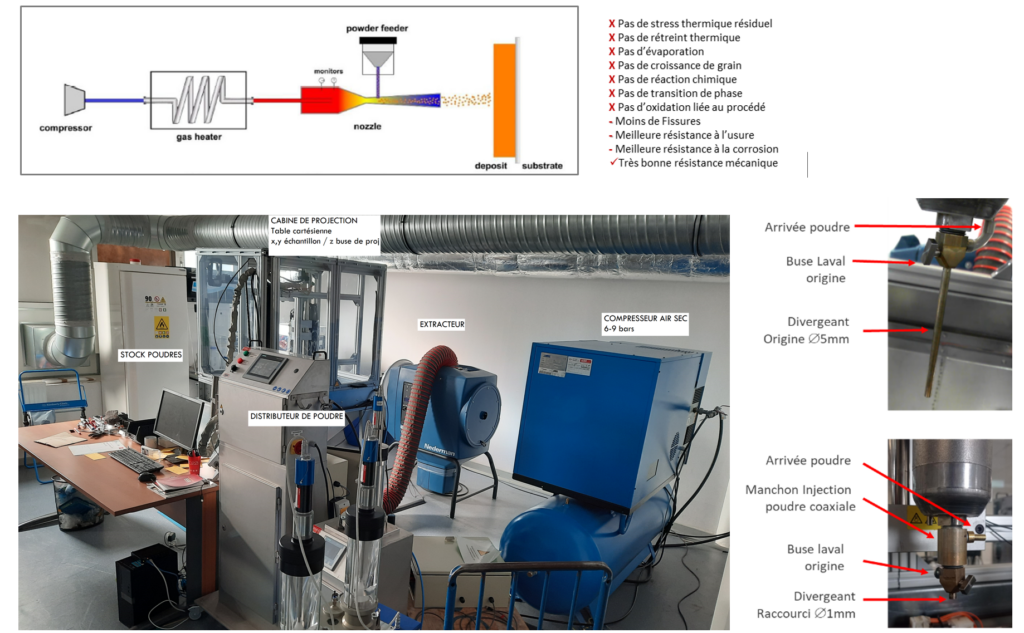

Combinatorial low pressure micro-Cold Spray equipment

Description

Deposition equipment by projection of powder(s) through a Laval nozzle using a hot carrier gas (dry air < 400°C). Low pressure version (4-9 bars) with injection of powder(s) into the divergent part of the nozzle. Dense deposits greater than 30µm thick of pure metals, metal composites and alloys from alloy powders or post process (TTH oven or laser). Rapid combinatorial synthesis of metal composites and alloys via 3 co-projection hoppers. Nozzles from 1 to 5 mm in diameter on Cartesian drive allowing the production of large surfaces up to 200 x 200 mm²; object rotation axis allowing deposit on cylinder. Automation of deposition with dynamic control of the thickness deposited via laser in situ. Dedicated to ductile metals, typically copper, aluminum, nickel and tin alloys.

Location

CEA Grand Est, 5 rue Marconi – Metz Technopole, 57070 METZ.

Technical characteristics

Associated targeted project